Inventory management is the lifeline of e-commerce businesses—excess inventory ties up capital, while stockouts directly lead to customer loss. Traditional Excel methods require manual data integration and calculation of reorder quantities, which are both time-consuming and prone to errors. This article will demonstrate how Excelmatic's AI capabilities can transform inventory optimization from daily manual labor to real-time automated management, with practical data demonstration tables included.

The Key Importance of Real-Time Inventory Optimization

Preventing Stockout Losses

- Amazon research shows: 30% of customers will turn to competitors when encountering stockouts.

- Impact: Directly leads to revenue loss and long-term damage to customer relationships.

Reducing Holding Costs

- Capital Lockup: Excess inventory ties up working capital.

- Storage Costs: Can consume up to 25% of total profits.

- Obsolescence Risk: Especially critical for fashion/electronics.

Improving Turnover Efficiency

- Best Practice: Rational restocking can increase inventory turnover by over 50%.

- Operational Advantage: Faster cash conversion cycle.

Traditional Excel vs. Excelmatic: In-Depth Inventory Optimization Comparison

Traditional Excel Workflow (Detailed Steps)

Step 1: Data Integration

Export raw data from multiple systems:

Sales_Report_2024Q3.csv(SKU, sales amount, date)Current_Stock.csv(SKU, inventory)Lead_Time.csv(SKU, supplier lead time)

Manually merge data using VLOOKUP:

=VLOOKUP(A2, Lead_Time!A:B, 2, FALSE) // Match lead time =VLOOKUP(A2, Current_Stock!A:B, 2, FALSE) // Match inventoryNeed to manually handle

#N/Amismatch errors.

Example Data Table:

| SKU | Product | 30-day Sales | Current Inventory | Lead Time (days) |

|---|---|---|---|---|

| SKU-ELC-101 | Wireless Headphones | 450 | 120 | 14 |

| SKU-WTCH-202 | Smartwatch | 320 | 80 | 21 |

Step 2: Reorder Calculation

- Daily Sales Volume:

=C2/30 - Safety Stock:

=ROUNDUP(E2*D2*1.2, 0) - Reorder Quantity:

=MAX(ROUNDUP(D2*(E2+7)-B2,0),0)

Formula Output:

| SKU | Daily Sales Volume | Safety Stock | Reorder Quantity |

|---|---|---|---|

| SKU-ELC-101 | 15 | 252 | 267 |

| SKU-WTCH-202 | 11 | 277 | 254 |

Step 3: Risk Analysis

Conditional Formatting to Mark Stockout Risks:

=IF(B2<Safety Stock*0.5,"Critical",IF(B2<Safety Stock,"Watch","Normal"))Manually filter slow-moving items (sales < 10% of inventory)

Send report to procurement team via email

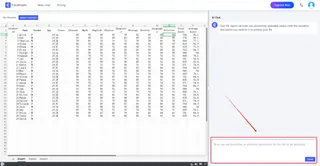

Excelmatic Solution

Step 1: Upload Data

Step 2: Enter Natural Language Instructions

Enter in the Excelmatic dialog box:

Optimize inventory based on the following rules:

- Calculate daily average demand based on the past 30-day sales.

- Safety Stock = Daily Average Sales × Lead Time × 1.2.

- Mark high-risk items with inventory below 50% of safety stock.

- List slow-moving items with 30-day sales less than 10% of inventory.

Step 3: Result Output

Workflow Comparison

| Tool | Traditional Excel | Excelmatic |

|---|---|---|

| Data Preparation | Manually clean CSV, delete invalid columns | Directly upload raw files, AI automatically cleans data |

| Rule Setting | Write complex formulas: | Describe business rules in natural language: |

=ROUNDUP((B2/30)*D2*1.2,0) |

“Safety Stock = Daily Average Sales × Lead Time × 1.2” | |

| Risk Identification | Manual screening: =IF(C2<E2*0.5,"High Risk","") |

Excelmatic automatically marks and grades risks, with additional solutions |

| Time Consumption | 4 hours (data + formulas + communication) | 8 minutes (upload + instruction + confirmation) |

Why Choose Excelmatic?

✅ Zero Learning Cost: No need to memorize formulas, describe needs in everyday language

✅ Deep Business Fit: AI understands industry terms (such as Safety Stock Turnover Rate)

✅ Decision Acceleration: From data to action in less than 10 minutes